We had the chance to catch up with Levi Chagnon and get a glimpse into his time spent in Tanzania working with African Plantations Kilimanjaro. Levi has been working to help develop new markets for the coffees grown at APK and has been given the opportunity to learn more than ever about coffee cultivation and logistics. We asked him seven questions.

1. What makes Tanzania's coffee culture distinct?

Where I was, in the Kilimanjaro region, they have a good local demand for coffee. That always makes for an interesting coffee culture at origin – especially in Africa. I feel like that is something you don’t really find in Uganda, Rwanda, or Burundi as much. Maybe in Kenya. The market there in Moshi and Arusha is evolving even into specialty consumption. A good local market for coffee makes it much easier for the growers to understand coffee consumption and quality.

2. Why did you choose to go there? What drives your commitment to exceptional coffee?

I couldn’t pass up the opportunity! I feel fortunate to surround myself with people that work in the growing of coffee. I have been on the roasting side of the chain for my entire career, so working with a farm has made me a more rounded person. Being there also changed my perspective on life a bit, too. The level of need in Africa is so great, and yet I was staying in a wealthy place comparatively.

3. Any moments of awe or surprise as you learned about the coffee business there?

The last five months have been a total revelation. The industry is totally moving toward new supply chain models – like the 30 kilo green coffee boxes, origin roasters, and direct trade sourcing. New markets are emerging at origin, and now farmers are interested in roasting the coffee they grow more than ever.

4 . Walk us through an average morning living in Tanzania.

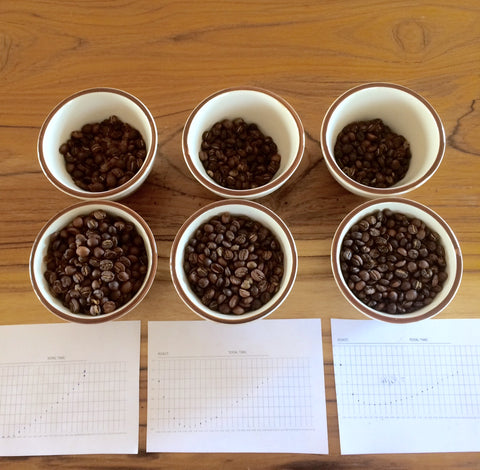

Ha! Okay, every morning I had breakfast, got ready, and walked out my front door to see Mt. Kilimanjaro! That thing is huge; photos really can’t do it justice. I want to try and climb that sucker someday if I get the chance. To get so work I drove an old Toyota for 15 miles of gravel road from the farm to the office. At the office, I was giving tours of the farms, cupping the quality of the coffees, developing new plans for the changing markets, or helping with presentations and events. It was pretty cool to be there.

5. Are you going back?

I want to go back for sure. Last I knew, I was going back in the end of January, but sometimes plans change. We really want to set up some new projects there and I’m really looking forward to doing some real roasting at origin. Plus, the amount of agro-knowledge you can get while there is limitless.

6. What's the future of African coffee? How does Tanzanian compare with, say, Ethiopian?

Tanzania’s production and quality are good and getting better. Every place is different and comes with unique challenges. We are seeing more single origin Tanzania offerings at cafes – but it would be nice if there were more. I am hoping that as we see more of a shift toward single origin consumption, we will see people seeking out more of a variety. So instead of always seeing a Ethiopian, Costa Rica, and Sumatra offered, we will see more of countries like Tanzania, Congo, Sulawesi…

7. Any crazy/funny/challenging cultural events?

I was totally unprepared for Africa in a good way. It was a surprise to get to go there and work, and more of a surprise to feel so welcomed while I was there. African Plantations Kilimanjaro has some awesome people working for them and it was a privilege to be there. Craziest things? I saw a semi-truck carrying our coffee almost tip over! We had overloaded a semi-truck with 12 tons of coffee en route to the mill from the farm. At the mill the driver goes to turn the truck around, and while doing so, drives through a big dip in the gravel road. The big semi-truck had one wheel almost 3 feet off the ground and was about to tip over right in front of us. Everyone at the mill was yelling and all of us were praying that truck didn’t tip over. It slammed back down and was stuck. We left for the mill that day at 10am and we were there until 8pm! I got a sweet lesson of the milling equipment and facility while we were waiting that day though so that made it worth it.